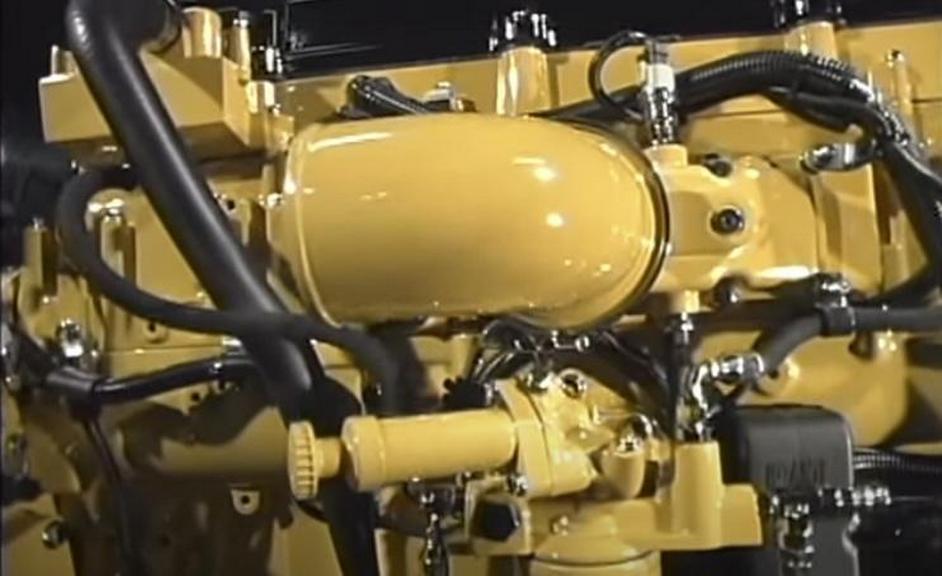

In the realm of heavy machinery, the c13 cat engine stands as a testament to power and reliability. Crafted by the industry giant Caterpillar, these engines are a staple in trucks, buses, and construction equipment. Despite their acclaimed status, certain models, specifically the 2005, 2006, and 2007 c13 cat engines, have encountered notable challenges. This article aims to shed light on these issues, providing a blend of insight and practical solutions.

Common Issues and Resolutions

The c13 cat engine’s resilience is sometimes tested by a range of problems, which we will explore alongside their solutions.

Oil Leaks

Oil leakage is a recurring concern with C13 CAT engines. It often occurs due to the wear and tear of gaskets and seals, which can lead to oil seepage and drips. To effectively prevent and tackle oil leaks, it is imperative to focus on regular maintenance and the timely replacement of gaskets and seals. Here is a more detailed breakdown:

- Gaskets and Seals: Regularly inspect gaskets and seals for signs of wear, brittleness, or damage. Replace any components that show signs of deterioration to maintain a proper seal;

- Engine Oil: Ensure that the engine maintains the correct oil level and adhere to the recommended oil change intervals as specified by the manufacturer. Using high-quality oil is essential for engine longevity.

By proactively addressing these aspects, you can significantly reduce the risk of oil leaks in your C13 CAT engine.

Overheating

Overheating is a common problem in C13 CAT engines and is typically a consequence of issues within the cooling system. Overheating can lead to engine damage and reduced efficiency. Preventing overheating requires a systematic approach to cooling system maintenance. Here are the crucial components and maintenance steps:

- Radiator: Clean the radiator often and check it for damage or clogs. Make sure that the radiator cap fits well. If problems are found with the radiator, fix them or get a new one;

- Water Pump: Verify that the water pump is functioning correctly. Look for signs of leakage or abnormal noises, as these may indicate a failing water pump. Replace it promptly if necessary;

- Coolant Levels: Monitor coolant levels closely and maintain them within the recommended range specified by the manufacturer. Insufficient coolant can lead to overheating.

By diligently attending to these aspects of your cooling system, you can effectively prevent overheating and its associated complications.

Turbocharger Failures

Turbocharger failures can be a concern with C13 CAT engines, and these failures often result from oil contamination or excessive engine strain. To minimize the risk of turbocharger failures and extend its lifespan, follow these best practices:

- Regular Oil Changes: Stick to the manufacturer’s recommended oil change intervals, and use high-quality oil. Clean oil reduces the risk of contamination and lubricates the turbocharger effectively;

- Avoid Excessive Engine Load: Operate the engine within recommended load limits to reduce stress on the turbocharger. Avoid excessive acceleration or prolonged high RPM operation.

By adhering to these maintenance practices, you can enhance the longevity and reliability of your C13 CAT engine’s turbocharger.

Faulty Injectors

Injector problems can manifest in C13 CAT engines due to wear and contamination, leading to decreased engine performance and fuel efficiency. Preventing injector issues requires consistent care and attention to detail. Here’s a more comprehensive breakdown:

- Regular Inspection: Inspect injectors at regular intervals for signs of wear, clogs, or contamination. Replace injectors promptly if they exhibit any of these issues;

- Clean Fuel: Ensure that clean, high-quality fuel is consistently used in your engine. Contaminated fuel can lead to injector problems, so regular fuel system maintenance is essential.

By following these maintenance steps, you can ensure that your C13 CAT engine’s injectors operate at their peak performance.

EGR Valve Problems

EGR (Exhaust Gas Recirculation) valve issues can be particularly prevalent in the 2005-2007 C13 CAT engine models. These issues often arise from carbon buildup or mechanical failures within the EGR system. To maintain the functionality of the EGR valve, especially in older models, it’s essential to take specific measures:

- Regular Cleaning: Clean the EGR valve at the recommended intervals to prevent carbon buildup, which can impede proper exhaust gas recirculation. Use an appropriate cleaning solution and follow the manufacturer’s guidelines;

- Part Replacement: If the EGR valve malfunctions due to mechanical issues or excessive wear, replacement may be necessary. Consult your engine’s service manual for guidance on proper replacement procedures.

By proactively addressing EGR valve issues through these maintenance steps, you can optimize the performance and emissions control of your C13 CAT engine.

Year-Specific Concerns

When it comes to maintaining and troubleshooting automobiles, it’s essential to be aware of year-specific concerns. Different model years can exhibit unique problems and challenges. Let’s delve into the issues specific to the years 2005, 2006, and 2007

Year 2005 Concerns

Year 2005 brought its own set of challenges for automobile owners. The following are the specific problems that were prevalent in vehicles manufactured during this year:

- EGR Valve Issues: One of the significant concerns in 2005 vehicles was the frequent occurrence of Exhaust Gas Recirculation (EGR) valve issues. These problems resulted in a reduction in fuel efficiency and overall engine performance. The EGR valve is responsible for recirculating a portion of exhaust gases back into the engine, reducing emissions. However, when it malfunctions, it can lead to rough idling, poor acceleration, and decreased fuel economy;

- Turbocharger Problems: Another noteworthy issue in 2005 vehicles was related to turbochargers. These problems were primarily due to design flaws in the turbocharger system. Turbochargers are responsible for boosting the engine’s power output by compressing air into the intake manifold. When they fail, it can result in a loss of power, poor acceleration, and increased exhaust emissions.

Year 2006 Concerns

Moving on to Year 2006, vehicle owners faced a distinct set of challenges:

- Increased Incidents of Oil Leaks: One of the prominent issues in 2006 vehicles was an increase in oil leaks. Oil leaks can occur for various reasons, including deteriorated gaskets, seals, or damaged components. These leaks can lead to low oil levels, which, if not addressed promptly, can cause severe engine damage;

- Electrical System Malfunctions: Another concerning problem in 2006 vehicles was related to the electrical system. Malfunctions in the electrical system could manifest in various ways, including issues with lights, power windows, the radio, and other electrical components. These problems were often attributed to wiring faults or issues with the vehicle’s control modules.

Year 2007 Concerns

In Year 2007, vehicle owners continued to grapple with specific issues:

- Persistent EGR Valve Complications: The EGR valve problems that had plagued 2005 vehicles persisted into 2007. These persistent complications were a source of frustration for many owners, as they resulted in decreased fuel efficiency and engine performance. Ensuring proper maintenance of the EGR valve became crucial for addressing this concern;

- Turbocharger Issues: Turbocharger issues, which had initially surfaced in 2005, continued to be problematic in 2007 vehicles. The design flaws that caused these issues needed to be addressed by manufacturers to prevent further inconvenience to owners. A malfunctioning turbocharger could still lead to reduced power and efficiency.

Maintenance Tips for Longevity

Ensuring the longevity of your vehicle involves more than just addressing year-specific concerns. To keep your automobile in top condition, consider the following maintenance tips:

- Regular Inspection: Regularly inspect key components like the EGR valve, turbocharger, and injectors;

- Timely Oil Changes: Frequent oil changes can prevent many issues related to engine parts like the turbocharger;

- Cooling System Care: Maintain the cooling system diligently to prevent overheating;

- Use of Quality Parts: Always replace worn-out parts with quality components to ensure the engine runs smoothly.

Conclusion

While the c13 cat engine is a model of industrial strength and efficiency, awareness of its common problems, particularly in the 2005-2007 models, is crucial for optimal performance. Understanding these issues and adopting a proactive approach to maintenance can significantly enhance the longevity and reliability of these powerful engines.

FAQ

Q1: What are the most common problems with the 2005 c13 cat engine?

A1: The 2005 model often faces EGR valve and turbocharger issues.

Q2: How can I prevent turbocharger failures in my c13 cat engine?

A2: Regular oil changes and avoiding excessive strain on the engine are key preventive measures.

Q3: Are there any recalls for the 2006 c13 cat engine problems?

A3: It’s advisable to check with a Caterpillar dealer for any specific recall information.

Q4: What maintenance practices can prolong the life of my c13 cat engine?

A4: Regular inspections, timely maintenance, and the use of quality replacement parts are essential.